Lost wax casting technique allows us to create jewelry and fashion accessories with the highest precision in tight schedules. However, for excellent results it is also necessary to use high-quality waxes.

In Masterix, we have developed the Masterwax line of wax, which our customers can easily recognize by its unique teardrop-shape. Produced and tested in our lab with state-of-the-art machinery, they offer the best solution for the specific needs of the different production techniques.

Masterwax: optimal results for every project

Thanks to extensive research on raw materials and market needs, we managed to create six different waxes for viscosity, resistance and cooling time.

As we have seen in our article on the features of the different waxes, each process corresponds to a specific wax. Just to give a few examples, for highly elaborate filigree, our Extra Fluid Red is the most suitable solution. For massive objects, on the other hand, the Massive Green is required and for settings the Dark Diamond.

But what happens when we want to produce a hollow-chamber jewel, such as beads, links for necklaces and bracelets or elaborate pendants?

Producing a hollow-chamber jewel with our Idrowax: all the steps

The production of hollow-chamber jewelry is first of all a necessity. Let’s think about the necklaces with large spheres. If they were solid, they would be very heavy and expensive, due to the considerable amount of precious metal used to produce them.

To produce hollow-chamber jewelry, we have developed a wax that can completely dissolve in contact with water or when it is subjected to ultrasound. Thanks to this soluble wax, it is possible to create hollow jewelry and accessories of any shape and size, always with the highest precision.

Our Idrowax guarantees perfectly reproduced models with sharp, precise details. It dissolves in warm water, making the whole process simple and fast, without any risk to the worker, also because this wax is completely non-toxic.

The process requires a few more steps than the traditional lost wax casting. Let’s see them in detail:

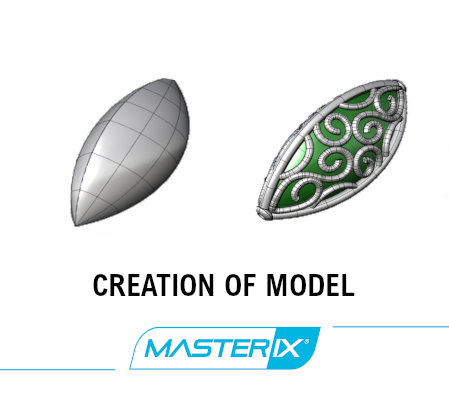

- The first step is to create the model for the jewel. What changes compared to traditional processes is that two models are made, one for the void inside and one for the outside

- It then goes to the creation of two silicone rubber molds, one for the hollow core and the other for the object to be replicated, that is the jewel or the accessory

- Once the two molds are ready, the wax is injected into the first mold to replicate the internal hollow model. The Idrowax hydrosoluble wax is injected and when it hardens, the mold is opened and the wax model is collected

- Once the two molds are ready, the wax is injected into the first mold to replicate the internal hollow model. The Idrowax hydrosoluble wax is injected and when it hardens, the mold is opened and the wax model is collected

- The hollow-chamber model is placed inside the second silicone rubber mold, which is used to replicate the outer part of the jewel. The next step is the second injection, with the classic wax for the jewel itself

- The hollow-chamber model is placed inside the second silicone rubber mold, which is used to replicate the outer part of the jewel. The next step is the second injection, with the classic wax for the jewel itself

- The second silicone rubber mold - with the hollow-core in soluble wax and the outside shape in “normal” wax - is placed on the cooler

- Once the mold and the wax have cooled down, it’s time to dissolve the soluble wax in warm water or by ultrasound

- At this stage, the 3D wax model is empty inside and perfectly identical to the model to be replicated.

From this point on, the process is the same as for massive jewels produced with normal waxes. The wax models are welded to the tree and then dived into a plaster solution. The plaster shell is fired at high temperatures, the wax melts and runs off and molten metal is poured. The plaster shell is opened, the pieces collected and then subjected to finishing or mechanical processing.

The advantages of quality

With our Idrowax it is possible to create 3D models that are internally hollow in short times and affordable prices. Thanks to its formulation, this nontoxic hydrosoluble wax guarantees defect-free models. The dissolution of the wax is fast and complete: in contact with warm water it melts without a trace.

The quality of the wax is crucial for the end results. The lost wax casting process ensures precision and optimization of the work cycle, but only on condition that the waxes are high-quality.

With our Masterwax waxes, it is possible to produce precise and stable models that keep their shape unaltered and do not get damaged during the extraction from the mold. And with our innovative hydrosoluble Idrowax, we can produce the highest quality hollow-chamber jewels.