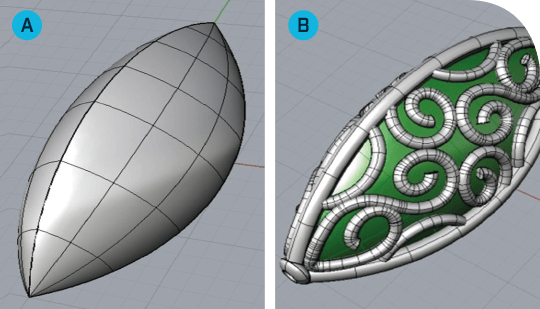

3D Inside-Hollow Models Creation Process

As part of large industrial fashion and jewellery productions, Idrowax represents the best solution to obtain a large number of excellent pieces in no time.

Unlike 3D printers, our injectors allow to get a large number of perfect quality pieces.

The creation of hollow inside models goes through distinct phases.

STEP 1 – Shaping

The first phase is about designing the pattern (es. using Rhynoceros or similar programs ). The model is created in three dimensions and two copies are made: one for the internal design, antoher for the external design.

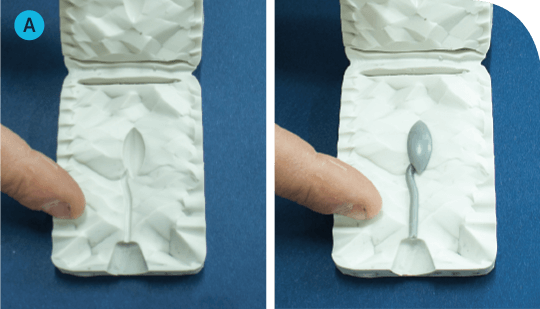

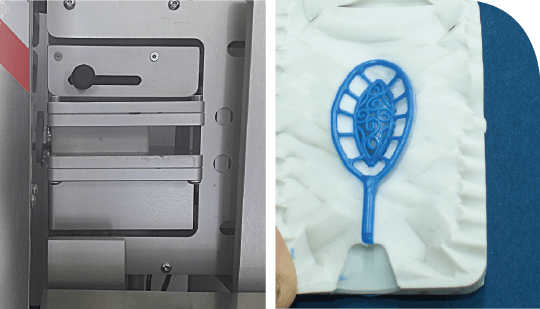

STEP 2 – Injection

In the second phase, wax is injected and the creation of the internal model of soluble wax starts.

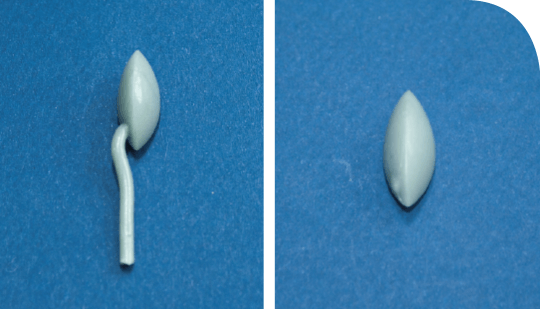

STEP 3 – Extraction

In the third phase, the soluble wax internal model is extracted from the mould and the model stem is cut.

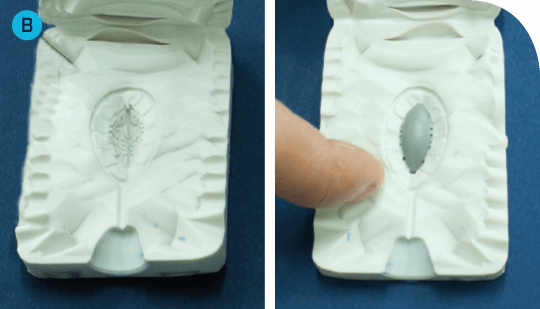

STEP 4 – Insertion

In the fourth phase , the soluble wax model is inserted in the mould to create the wax external model.

STEP 5 – Second Injection

When the external model is created, another wax injection is made. The result is a three dimensions external model with a soluble wax model inside.

STEP 6 – Melting

In the sixth phase, the soluble wax piece is melted into lukewarm water.

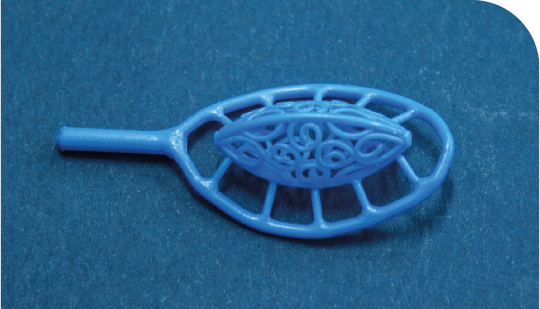

STEP 7 - Model

Here is the 3D hollow inside wax model, identical to the designed model.

STEP 8 – Finished Piece

After the fusion, the 3D hollow piece is done.