Masterix uses its decades of experience to develop the highest- performance technologies for the production of jewelry and fashion accessories, designing increasingly innovative solutions to meet the needs of its customers.

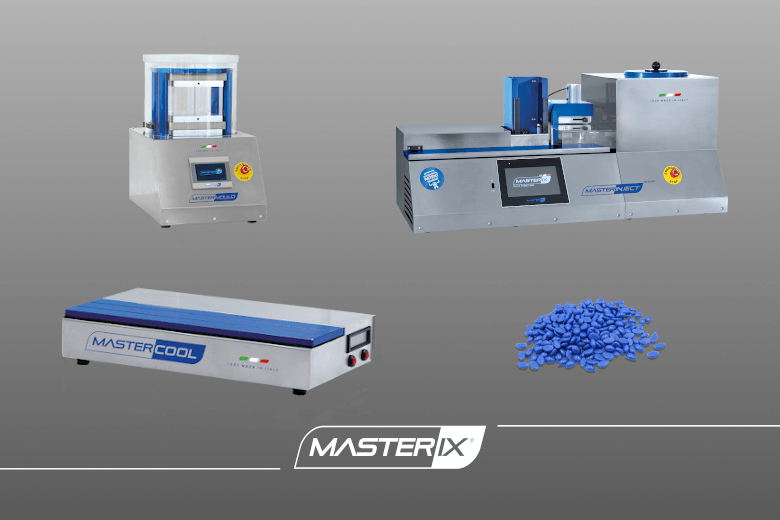

Over the years, we have engineered innovative machines for the various production phases, developing a complete line of products to optimize the lost-wax casting process.

Let's see in detail which are the flagship products.

Vacuum vulcanizer and pump for hot vulcanization of molds

The lost-wax casting process starts with the vulcanization of rubber molds. The vulcanizer that we propose within the complete line is the VLC-180 which, in combination with the VAP 18 pump, vulcanizes silicone rubber under vacuum at high temperature, so as to remove humidity and microbubbles from the rubber.

The VLC 180 vulcanizer is fully automatic, with intuitive touch screen control. It reaches a temperature of 200° C, a closing pressure of 10 Bar and has an unlimited number of programs.

The rubber molds obtained with this technique are free of imperfections. In addition, they are durable and can be used many times, ensuring time and cost optimization for our partner companies.

Being able to manage in complete autonomy and with the best results such an important step, is undoubtedly a significant advantage for the company. Many companies in the sector outsource the vulcanization of rubber molds to external companies. The outsourcing of a service, which by the way has a great impact on the end results, implies additional costs, does not protect the confidentiality of the projects and generates dependence on an external supplier.

Automatic injector MI-03

Wax injection is the central step in lost-wax casting. Our fully automatic injector guarantees a continuous production cycle and wax models of the highest quality.

Compared to the manual versions, automatic injectors have several advantages. With them, companies can

- save time: the operator can directly set the parameters on the touch screen, optimizing the working time

- reduce waste and increase annual growth: with the automatic injector, the operator can configure preset times and levels of pressure that will remain constant over time for the selected models. This leads to the reduction of waste and the increase of annual production.

Masterwax Universal Blue, our universal wax

Even the best injector on the market needs a top-quality wax to create precise and perfectly replicable models.

As the name suggests, Masterwax Universal Blue is a universal wax suitable for all processing. Its most prominent feature is precisely its versatility. It can be used for very different processing - from the thin filigree jewelry to the massive objects - and allows the continuous cycle manufacturing, with no need to stop production to change the type of wax.

In addition to being fluid, flexible, elastic and resistant, Universal Blue wax has excellent shape memory. It leaves no melting residue and can withstand operating temperatures up to 80° C.

Mold coolers CO-04D & CO 06-D

Mold cooling is crucial for production speed. In fact, if we had to wait for the natural solidification of the waxes, we would need much more time and many more silicone rubber molds.

As we have seen in our previous insight, mold cooling prevents defects and imperfections. Our CO-04D & CO-06D mold coolers are the most requested on the market thanks to their compact dimensions and low energy consumption.

With Masterix coolers it is possible to:

- speed up times and, consequently, increase productivity

- optimize the investment: you need less rubber molds because they can be reused immediately after extraction

- ensure the success of pieces without imperfections, thus facilitating the extraction of the model

- protect the molds from prolonged exposure to high temperatures after wax injection.

The desired temperature is set directly on the LCD display and is kept constant until the end of the process.

MasterDB software, Industry 4.0

What we have discussed so far is state-of-the-art machinery, designed to optimize production and guarantee the highest quality standards. But Masterix innovation goes well beyond that.

Our Master BD software is the key to interconnection with Industry 4.0 because it

- extracts and sends data to the machine

- automatically downloads daily, monthly or yearly stats

- sends and checks production orders for each set up and connected machine.

It is supplied by Masterix in a simple USB key and is the safest and most rational system for managing all the data from the various machines.

Our complete line, composed of

- Hot vulcanizer VLC-180 and high vacuum pump VAP 18

- Automatic injector and pump VAP 14 or VAP 18 depending on power

- Universal Blue wax

- Rubber mold coolers

- MasterDB software for data management and rationalization

is a real strategy for the production of jewelry and fashion accessories.

Thanks to our complete line, our customers will have the opportunity to optimize the lost-wax casting process using high-quality and high precision made in Italy products without outsourcing any processing.